Designers, hotel brands, and procurement teams increasingly choose wood veneer panels to achieve warm, luxurious, and highly consistent interiors. Veneer delivers the natural beauty of wood while offering greater stability, broader design flexibility, and far better cost control than solid wood—critical advantages for large hospitality projects.

But not all veneer panels perform the same. Natural veneer, engineered veneer, and specialty textured panels each create different visual outcomes, durability levels, and pricing profiles. At the same time, factors such as veneer grading, grain matching, substrate selection, moisture resistance, and finishing quality directly influence how well the panels will age in a 5-star hotel environment.

This guide gives hotel developers and procurement managers a clear, practical framework for choosing the right wood veneer panels. You’ll learn how veneer is made, the differences between natural and engineered options, quality indicators to check before ordering, and the design trends shaping today’s luxury hospitality interiors.

1.What Are Wood Veneer Panels?

Wood veneer panels are decorative materials made by bonding thin slices of natural or engineered wood (usually 0.3–3mm thick) onto a base panel such as plywood or MDF. The process combines the natural beauty of wood with the structural stability of man-made substrates — ideal for both interior wall cladding and custom hotel furniture.

1. Natural Veneer Panels

Made from real wood logs, each panel displays unique grain and texture — perfect for high-end applications where authenticity is valued.

2. Reconstituted (Engineered) Veneer Panels

Also known as tech veneer or reconstructed veneer, this material is produced by slicing and dyeing fast-growing, sustainable wood species such as poplar or ayous. The processed veneers are reassembled and pressed to replicate the appearance of premium hardwoods like walnut, oak, or ebony — but at a fraction of the cost.

This technique not only enhances cost efficiency but also ensures color and grain consistency across large hotel projects, making it ideal for international chains that require visual uniformity in guestrooms, corridors, and public areas.

3. Textured Wall Panels/Custom Wood Veneer Panels

Unlike smooth surfaces, textured wood veneer wall panels add depth and tactile richness to interiors.

- 3D carving and fluting create visual rhythm.

- CNC precision ensures perfect symmetry and dimensional consistency.

- Customizable with up tounique patternsin different wood species and finishes.

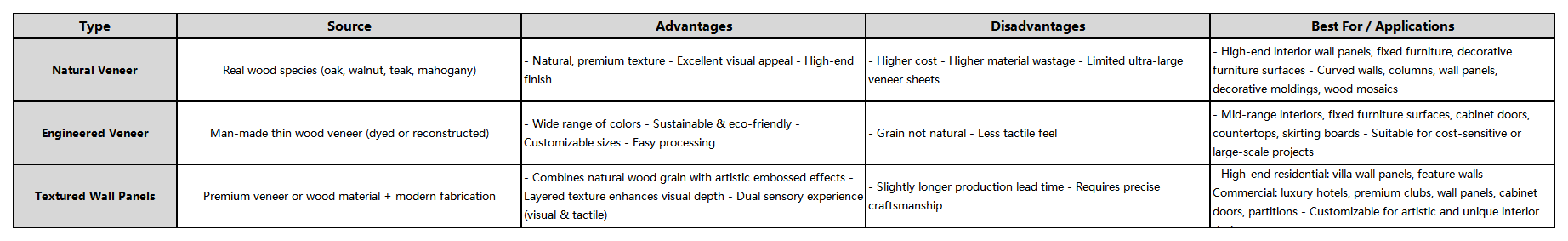

Comparison Table:

2. Wood Veneer Production Process

How is wood veneer produced?

The general process for creating wood veneer is as follows:

Processing raw timber → Manufacturing wood veneer sheets → Bonding veneer sheets → Hot-pressing and laminating → Surface finishing.

1. Processing Raw Timber

Selected high-quality logs are debarked and conditioned through steaming or boiling to improve flexibility for slicing.

Logs are then sliced into thin veneers, typically ranging from 0.4 mm to 1.0 mm in thickness.

This stage ensures the veneer maintains consistent grain, color, and surface texture.

2. Collecting and Drying Veneers

Freshly sliced veneers contain high moisture levels and must be dried to stabilize them for further processing.

Edges are trimmed precisely using shearing machines to ensure uniform dimensions and clean alignment for the joining process.

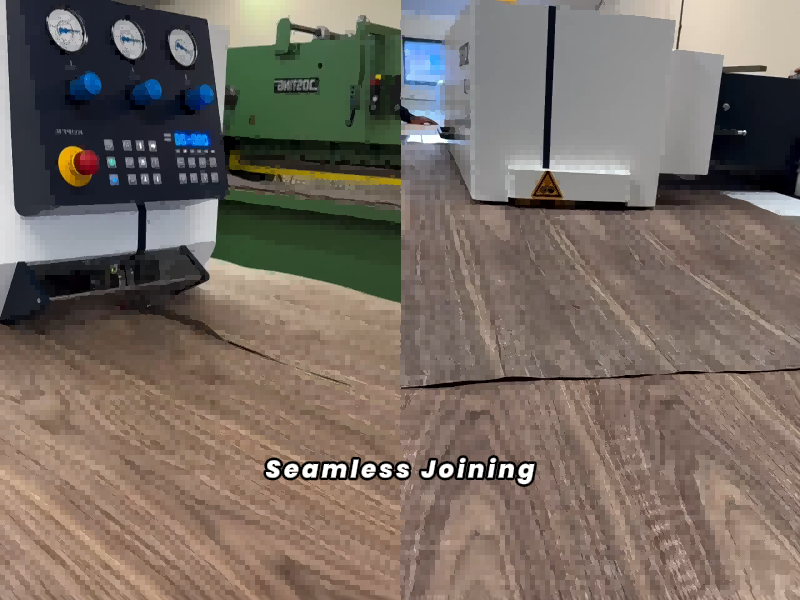

3.Wooden Veneer Joining

Seamless Joining: Merge veneers through machine hot pressing.

4. Gluing and Pressing

- Glue Application:Apply eco-friendly adhesive evenly across the base substrate (commonly MDF, plywood, or particleboard).

- Hot Press Bonding:Use thermal pressure to bond the veneer layers to the substrate.

5.Surface Finishing

Once lamination is complete, panels undergo surface sealing and finishing, including sanding, staining, and coating.

These steps enhance the veneer’s color depth, scratch resistance, and moisture protection, producing ready-to-install decorative panels that meet luxury hotel standards.

3. Standard and Custom Sizes for Hotel Veneer Projects

In commercial production, wood veneer panels are typically manufactured in a standard size of 2440/3050 × 1220 mm, which fits most hotel wall claddings, wardrobes, and joinery applications.

This universal format simplifies transportation, installation, and material coordination with other FF&E components.

However, luxury hotel projects often require greater design flexibility — where custom veneer panels provide significant advantages:

- Tailored Dimensions and Thickness: Panels can be cut to precise room heights or modular furniture sizes, minimizing on-site trimming and improving installation efficiency.

- Substrate Flexibility:Choose from fire-rated plywood, MDF, or composite cores that comply with international hospitality safety standards (e.g., BS 476, EN 13501).

- Finish and Edge Matching:Custom factories can sequence veneers for perfect grain continuity across walls or furniture surfaces — an essential detail for five-star visual harmony.

- Sustainability Options:Custom cutting reduces waste, optimizes yield, and supports eco-friendly production practices.

Partnering with a specialized hotel furniture manufacturer like IFC FF&E ensures precision-engineered panel sizing and professional coordination between veneered wall panels, fitted furniture, and room millwork packages.

This integration can reduce material waste by up to 30% and significantly shorten project lead times while maintaining strict quality control.

4.How to Choose Wood Veneer Panels for Hotel Projects

Selecting the right wood veneer panels for hotel projects goes beyond aesthetics—it affects durability, maintenance, and overall guest experience. Here’s a structured approach to making the best choice:

1.Veneer Grade

- AA Grade: Nearly flawless appearance, ideal for high-visibility areas like lobby walls or luxury suites.

- A/B Grade: Attractive natural texture with minor imperfections; suitable for standard guest rooms or decorative elements.

- C Grade: More affordable, but may show color variations or small defects; good for non-critical areas.

2.Material and Durability

Use substrates like MDF, plywood, or HPL cores for stability.

Ensure panels can resist warping, moisture, and heavy usage, especially in high-traffic areas.

3.Pattern and Color Matching

Check consistency of wood grain and color across panels.

For feature walls or continuous surfaces, ensure proper alignment to achieve a seamless, premium look.

4.Size and Customization

Standard panels (e.g., 4×8 ft) are easy to source and install.

Custom-cut panels are essential for unique architectural elements, curved walls, or bespoke furniture.

5.Supplier Evaluation and Service

Choose suppliers who provide one-stop solutions, including cutting, finishing, and delivery.

Reliable communication, quality control, and experience with hotel projects reduce installation errors and project delays.

By carefully considering these factors, hotel designers and developers can select wood veneer panels that balance visual appeal, durability, and cost-efficiency, ensuring long-lasting quality and a luxurious interior experience for guests.

5. Applications in Hotel Interiors

Wood veneer panels have become one of the most preferred surface materials in 5-star hotel design. Their warmth, tactile quality, and high-end aesthetic allow designers to elevate guest areas while maintaining durability and brand consistency. Today’s luxury hotels increasingly use veneer not just as wall finishes, but as a core architectural material across guestrooms, public spaces, and custom FF&E.

Below are current design trends from recent 5-star hospitality projects, showing how wood veneer panels are redefining modern hotel interiors. These trends reflect global insights from leading hotel brands and industry reporting (source: Hospitality Design Trends, HospitalityNet).

1. Feature Walls in Lobbies and Reception Areas

Luxury hotels now favor large-format veneer panels to create warm, sculptural lobby environments. Natural veneer with book-matched or slip-matched grain patterns helps create a cohesive brand identity from the moment guests enter.

Common selections: walnut, oak, reconstituted ebony

Design effects: grandeur, visual continuity, premium arrival experience

2. Guestroom Headboards and Bed Wall Systems

Veneer panels are increasingly replacing upholstered headboards due to their:

durability against high room turnover

easier maintenance

consistent appearance across hundreds of rooms

Integrated lighting channels, CNC-textured surfaces, and custom stain colors allow owners to achieve a signature guestroom design without excessive cost.

3. Restaurants, Bars, and Lounge Spaces

Hospitality designers favor wood veneer for its ability to create:

intimate dining areas

warm bar atmospheres

natural transitions between open and closed spaces

Engineered wood veneer is especially popular due to its color uniformity, which ensures consistent mood lighting across large F&B areas.

4. Textured Veneer for Contemporary Luxury Suites

3D-textured veneer panels have become a defining element in modern hotel suites. CNC-crafted grooves, fluted profiles, and geometric designs enhance tactile and visual expression without sacrificing structural stability.

Design benefits:

depth and shadow play

elevated craftsmanship

visual zoning inside suites

6. Spa & Wellness Facilities

Moisture-resistant veneer panels combined with engineered substrates are ideal for spa, sauna, and treatment rooms. They provide a premium natural look while meeting hygiene and humidity requirements.

6.How to Evaluate Suppliers for Custom Veneer Panels

Selecting the right wood veneer panel supplier is as critical as choosing the right material. For luxury hotel projects, the supplier’s expertise, quality control, and delivery reliability directly influence both construction progress and brand presentation.

Here’s a practical checklist for procurement teams and project managers:

FAQ

Can these veneers be used in humid climates?

Yes! Our proprietary coating protects against warping in humidity up to 85% RH – ideal for coastal resorts and spas.

Can I customize the size and color of the panels?

Yes, we offer custom sizes, colors, and surface finishes to match your project requirements.

What is the fire resistance rating of these panels?

Our panels meet B1 fire resistance standards, with higher ratings available upon request.

What’s the lead time for custom orders?

Standard sizes ship in 30 days. Custom stains/sizes require 45-60 days.